How to Spot Potential Gearbox Problems: A Comprehensive Guide for Identifying and Addressing Common Issues

- Autolast Ghana

- Dec 29, 2024

- 2 min read

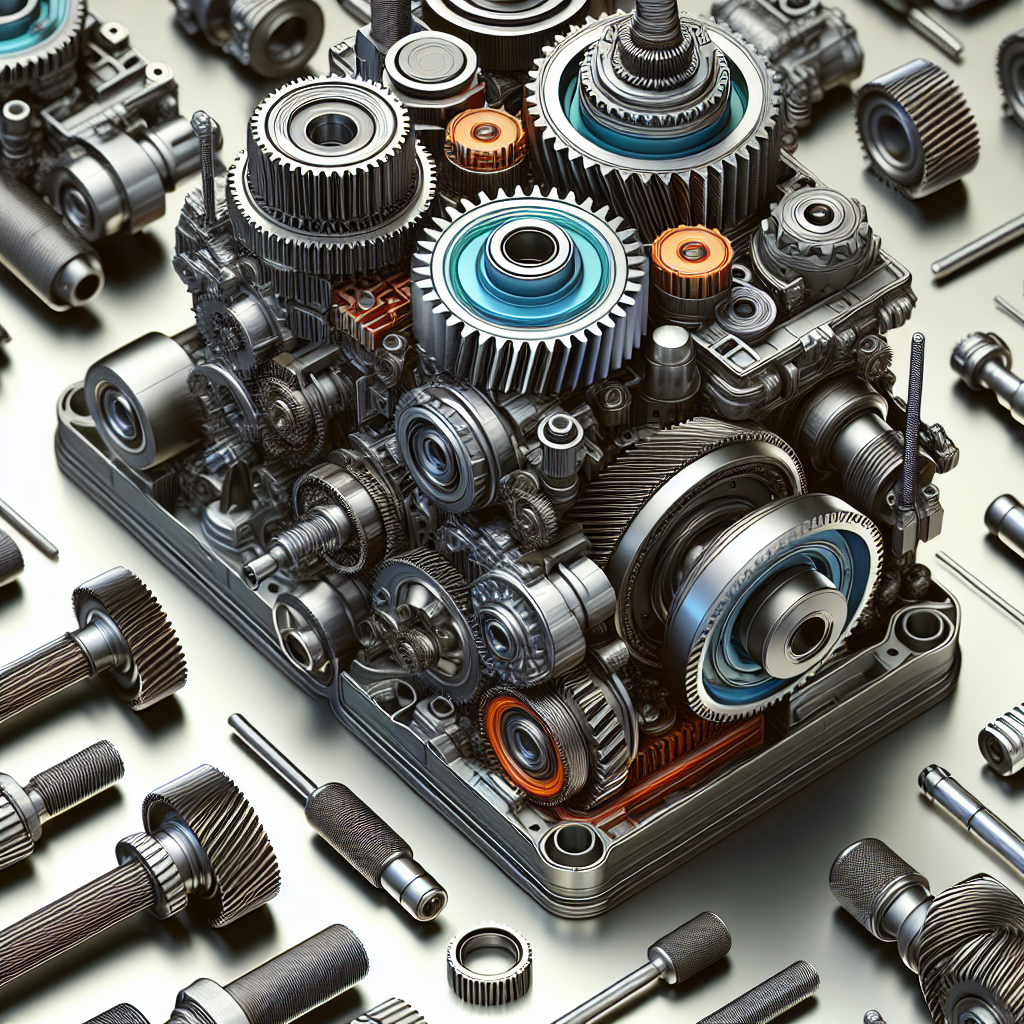

Gearboxes are vital components of many mechanical systems, from vehicles to industrial machinery. They play a crucial role in the smooth operation of these systems, but like any complex mechanism, they are prone to wear and tear over time. Recognizing the signs of a failing gearbox early on can prevent costly repairs or replacements down the line. In this guide, we will explore common gearbox issues, how to identify them, and the steps you can take to address them effectively.

Common Signs of Gearbox Problems

1. Unusual Noises

One of the most common indicators of gearbox issues is unusual noises during operation. If you hear grinding, whining, or clunking sounds coming from your gearbox, it could be a sign of worn-out gears or lack of lubrication.

2. Leaking Fluid

Leaking fluid around the gearbox area is a red flag that should not be ignored. Low fluid levels can lead to increased friction and overheating, causing further damage to the gearbox components.

3. Difficulty Shifting Gears

If you are having trouble shifting gears smoothly, such as experiencing resistance or gear slippage, it could indicate underlying gearbox issues. This can also manifest as delayed engagement when switching between gears.

4. Vibrations

Excessive vibrations during operation can signal misaligned gears or worn-out components within the gearbox. These vibrations can be felt through the vehicle or machinery and are a clear warning sign of potential problems.

Addressing Gearbox Issues

1. Regular Maintenance

The best way to prevent gearbox problems is through regular maintenance. Ensure that the gearbox is adequately lubricated and check for leaks or abnormal signs during inspections.

2. Fluid Checks

Monitor the gearbox fluid levels regularly and top up as needed. Using the manufacturer-recommended fluid type is crucial for optimal gearbox performance and longevity.

3. Professional Inspection

If you suspect gearbox issues but are unsure of the exact problem, it's best to seek the expertise of a professional mechanic or technician. They can diagnose the issue accurately and recommend the necessary repairs.

4. Timely Repairs

Addressing gearbox problems promptly can prevent further damage and extend the lifespan of the gearbox. Ignoring small issues can lead to more significant and costly repairs in the future.

Gearboxes are intricate components that require attention and maintenance to function correctly. By staying vigilant for the early signs of gearbox problems and taking proactive steps to address them, you can ensure the longevity and efficiency of your mechanical systems.

Remember, a well-maintained gearbox is the foundation of smooth and hassle-free operation, so don't overlook the importance of proper care and timely repairs. With these tips in mind, you can keep your gearbox running smoothly and avoid unnecessary downtime due to unexpected failures.

Gearbox issues may seem daunting, but with the right knowledge and approach, you can tackle them head-on and keep your systems running at peak performance.

Stay tuned for more expert tips and guides on maintaining your mechanical components and optimizing performance!

Stay Gear-Ready!

Gearbox problems, Gearbox maintenance, Identifying gearbox issues, Gearbox repairs

Comments